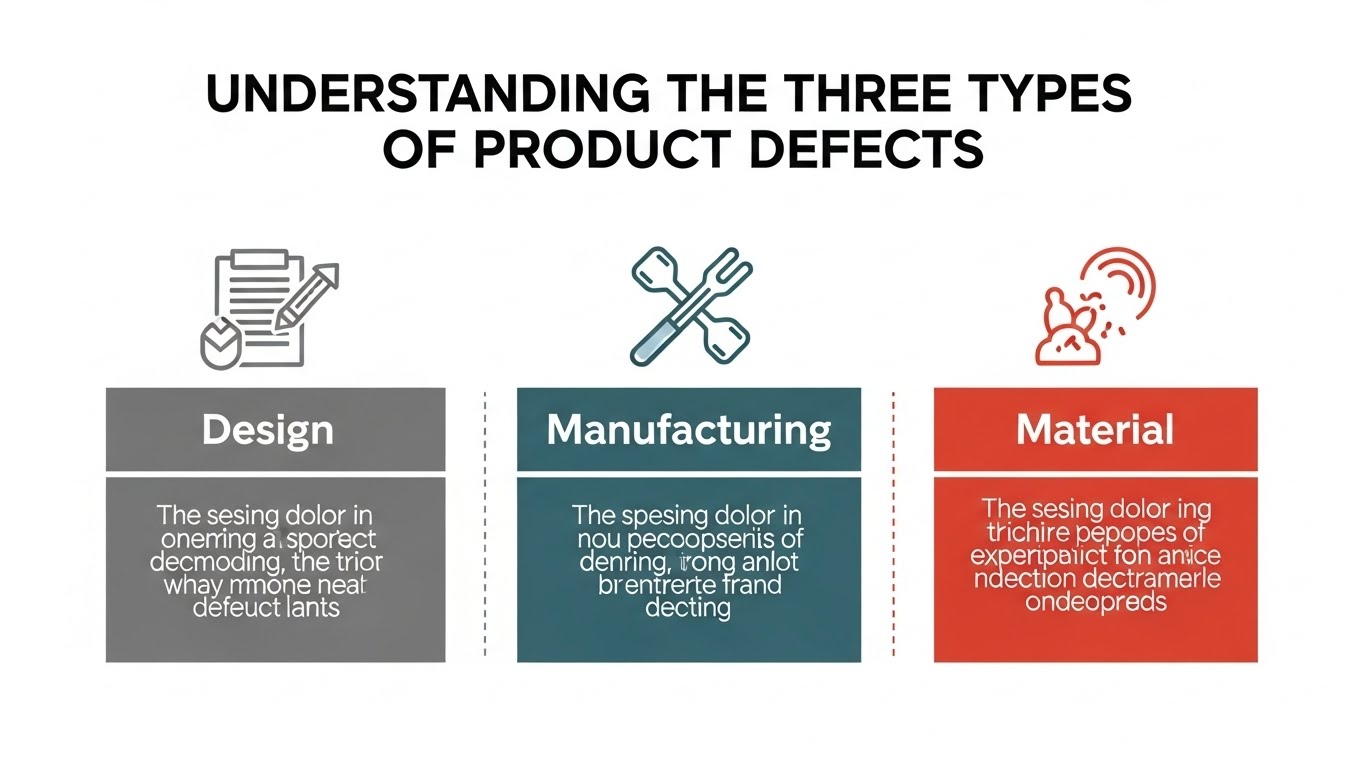

Understanding the Three Types of Product Defects

When a consumer product causes harm, the law recognizes three primary types of defects that may hold manufacturers responsible: design defects, manufacturing defects, and failure-to-warn defects. Understanding the difference between these categories is crucial for anyone pursuing a product liability claim. Each type identifies a different point of failure in the development, creation, or marketing of a product.

Whether the defective product is a car part, medical device, children’s toy, or household appliance, identifying the specific type of defect helps determine liability and the strength of your legal claim. For related topics, visit our Product Liability resource page.

1. Design Defects

A design defect occurs when a product is inherently unsafe due to the way it was planned or engineered. In these cases, the entire line of products is dangerous—even if manufactured correctly. The issue lies in the blueprint, not the assembly.

What Makes a Design Defect Legally Actionable?

To qualify as a design defect, the injured party typically must show that:

- The product was designed in a way that made it unreasonably dangerous.

- A safer, practical alternative design existed.

- The injury occurred because of the product’s flawed design.

For example, an SUV with a high center of gravity prone to rollovers would fall under design defects. Even if every SUV was perfectly assembled, the design itself creates danger.

Common Examples of Design Defects

- Medical devices with structural weaknesses

- Vehicles prone to fuel tank explosions

- Children’s toys with choking hazards built into the design

- Electronics designed without proper fire prevention measures

2. Manufacturing Defects

Manufacturing defects occur when the product’s design is safe, but something goes wrong during production. This error affects only certain units or batches, not the entire product line.

A manufacturing defect means the product deviated from its intended design, causing it to become dangerous. These cases often rely on physical evidence—showing the flaw directly in the product.

What Causes Manufacturing Defects?

- Contaminated materials

- Incorrect assembly or installation

- Faulty mechanical equipment on production lines

- Human error during assembly

- Missing or substituted components

For example, a batch of bicycle helmets manufactured with substandard foam would be considered a manufacturing defect—even though the design was safe.

Common Injuries from Manufacturing Defects

- Severe burns from improperly wired electronics

- Broken bones from defective ladders or tools

- Head injuries from faulty protective equipment

- Vehicle crashes caused by defective brakes or steering parts

3. Failure to Warn (Warning Defects)

A failure-to-warn defect, also known as a marketing defect, happens when a product lacks adequate instructions or warnings about potential risks. Some products cannot be made entirely safe, but manufacturers must clearly identify dangers and proper use.

What Counts as a Warning Defect?

Manufacturers are legally obligated to provide:

- Clear safety warnings

- Proper instructions for use

- Hazard disclosures

- Risk explanations for foreseeable misuse

Failure to include these warnings can make a product unreasonably dangerous, even if it is designed and manufactured correctly.

Examples of Warning Defects

- Prescription drugs without adequate side-effect warnings

- Cleaning chemicals missing hazard labels

- Power tools lacking safety instructions

- Children’s products missing choking hazard warnings

Why Understanding Product Defects Matters

Identifying the type of defect is essential for building a strong product liability claim. It helps determine which party may be responsible, such as the:

- Product manufacturer

- Parts or component manufacturer

- Distributors or retailers

- Engineers or designers

Each defect type requires different forms of evidence, expert testimony, and investigative methods. For example, a design defect case may require engineering analysis, while a manufacturing defect may rely heavily on physical inspection and quality control documentation.

What to Do If You Were Injured by a Defective Product

If you believe a defective product caused your injuries, take the following steps:

- Seek medical attention immediately.

- Preserve the product in its original condition—do not repair it.

- Document the incident with photos, videos, and witness statements.

- Check for product recalls through the CPSC or manufacturer.

- Consult a product liability attorney to evaluate your claim.

You can also explore related topics on our Product Liability page for additional legal resources.

Final Thoughts

Design, manufacturing, and warning defects each pose unique dangers to consumers. Understanding these categories empowers injured victims to recognize their rights and pursue compensation when harmed by a dangerous product. With proper legal guidance and strong evidence, victims can hold negligent manufacturers accountable and prevent future harm to others.